1

Which filaments are compatible?

Filasophia can be used with ABS, ASA, CPE, HDPE, HIPS, Nylon, PC, PET, PETG, PLA, PP, PVC, PVDF, Glass and Carbon Fiber Reinforced materials.

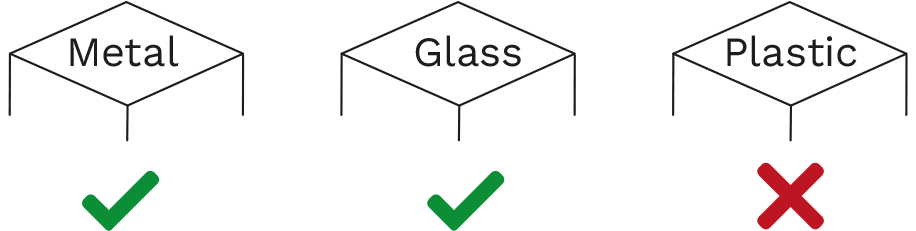

Filasophia products are optimized for glass and metal. They may damage plastic print plates. For best performance, use Filasophia plates. Contact us for custom size requests.

ABS

ASA

CPE

HDPE

HIPS

PA6

PC

PET

PETG

PLA

PP

PVC

PVDF

TPE

TPU

–GF

–CF