User Guide

1. Which Filaments is it Suitable For?

You can use this product with PLA, ABS, ASA, Polypropylene, PET, CPE, TPE, TPU, HIPS, PVC, HDPE, PA6 (Nylon), PC, Glass, and Carbon Fiber-Infused Materials.

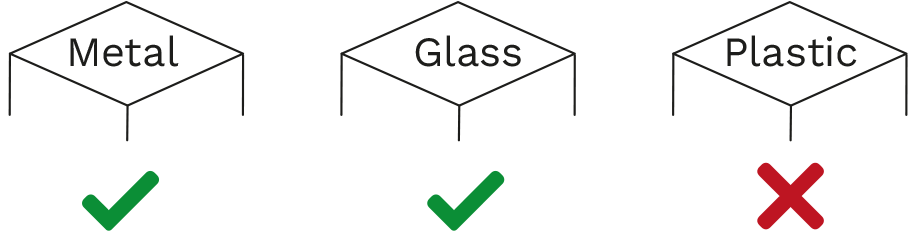

Filasophia products are optimized for glass and metal surfaces. They may damage plastic build plates. For optimal performance, use Filasophia build plates. Contact us for custom size requests.

2. How to Use Filasophia Adhesive?

a. Before the print on the build plate surface, it should be: Smooth, Clean, Oil-free, Dry

Before the print on the build plate surface, it should be: Smooth, Clean, Oil-free, Dry

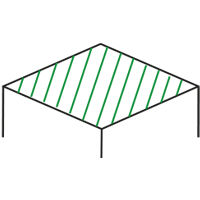

b. Apply Filasophia Adhesive to the build plate with a spatula to create a thin film.

Apply Filasophia Adhesive to the build plate with a spatula to create a thin film.

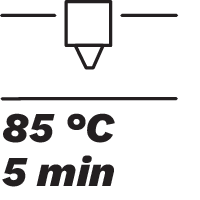

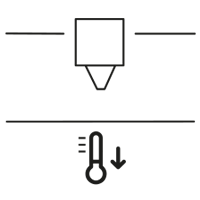

c. Place the build plate in the printer and preheat it to 85°C for 5 minutes. Apply this heating step to create an even film layer for each filament.

Place the build plate in the printer and preheat it to 85°C for 5 minutes. Apply this heating step to create an even film layer for each filament.

3. How to Use Filasophia Adhesive? (...)

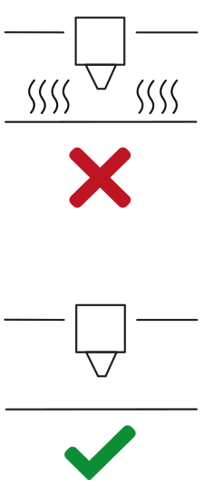

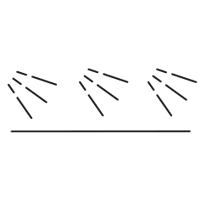

d. As the build plate heats up, you will observe the film drying and vapor formation on the plate.

As the build plate heats up, you will observe the film drying and vapor formation on the plate.

The cessation of vapor indicates readiness for printing. Do not begin printing until the film is dry.

The drying time varies depending on the thickness of the film. Print success can vary depending on filament material, printing method, and printer settings.

4. How to Use Filasophia Remover?

After the print is completed, wait for it to cool down.

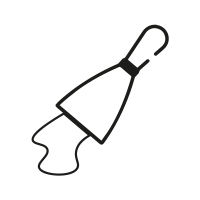

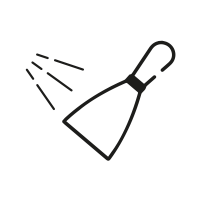

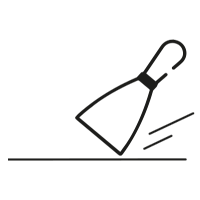

After the print is completed, wait for it to cool down. To remove the print from the build plate, apply Remover Spray to both sides of the spatula. Avoid spraying directly onto the print to prevent damage.

To remove the print from the build plate, apply Remover Spray to both sides of the spatula. Avoid spraying directly onto the print to prevent damage. Use a spatula to separate the print from the build plate.

Use a spatula to separate the print from the build plate. After removing the print, apply Remover Spray to the entire build plate.

After removing the print, apply Remover Spray to the entire build plate.5. How to Use Filasophia Remover? (...)

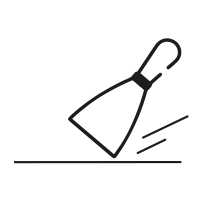

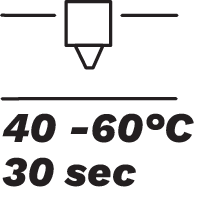

Set the build plate temperature to the optimal range of 40-60°C, depending on your adhesive layer thickness preference, wait for half a minute (30 sec)*

Set the build plate temperature to the optimal range of 40-60°C, depending on your adhesive layer thickness preference, wait for half a minute (30 sec)* Use a spatula to easily lift off the entire film.

Use a spatula to easily lift off the entire film.*If the printer is already at the desired temperature, begin the scraping process 2 minutes after placing the build plate.

Clean the build plate with a clean cloth. Ensuring that there is no leftover Remover residue is essential to maintain the quality of your next print.

Clean the build plate with a clean cloth. Ensuring that there is no leftover Remover residue is essential to maintain the quality of your next print. *You can use a cloth with Remover applied to clean any film residues under the printed part.

6. Print Has Detached from the Build Plate - What Can I Do?

Expansion coefficient, surface free energy, crystallization and glass transition temperature, polymer structure of the filament material also build plate material, print design, slicer settings and adhesive behavior are critical parameters for print success. Check whether the print has detached from the adhesive film or the build plate.

If the print has detached from the film;

- Ensure the film surface is completely dry.

- Reduce the bed temperature.

- Decrease the print speed.

- Lower the extruder temperature.

- Reduce the infill percentage.

- Set the build plate, first layer temperature to 95°C and the other layers as 77-85°C

- Use a heated enclosure for low surface free energy, high expansion coefficient filaments like PVDF and POM.

7. Print Has Detached from the Build Plate - What Can I Do?(...)

If the adhesive film has detached from the build plate:

- Ensure the build plate is oil-free, clean, and dry.

- Clean the build plate with isopropyl alcohol.

- Apply a thicker film for added durability.

- For prints with a longer height and also high thermal expansion coefficient like ABS and ASA, it is recommended to use a thicker adhesive.

- Set the build plate, first layer temperature to 95°C and the other layers as 77-85°C

- Temperatures above 105°C can reduce adhesive performance; it is recommended not to exceed this temperature without a heated enclosure.