Precision Unleashed: 3D Printing with Polypropylene

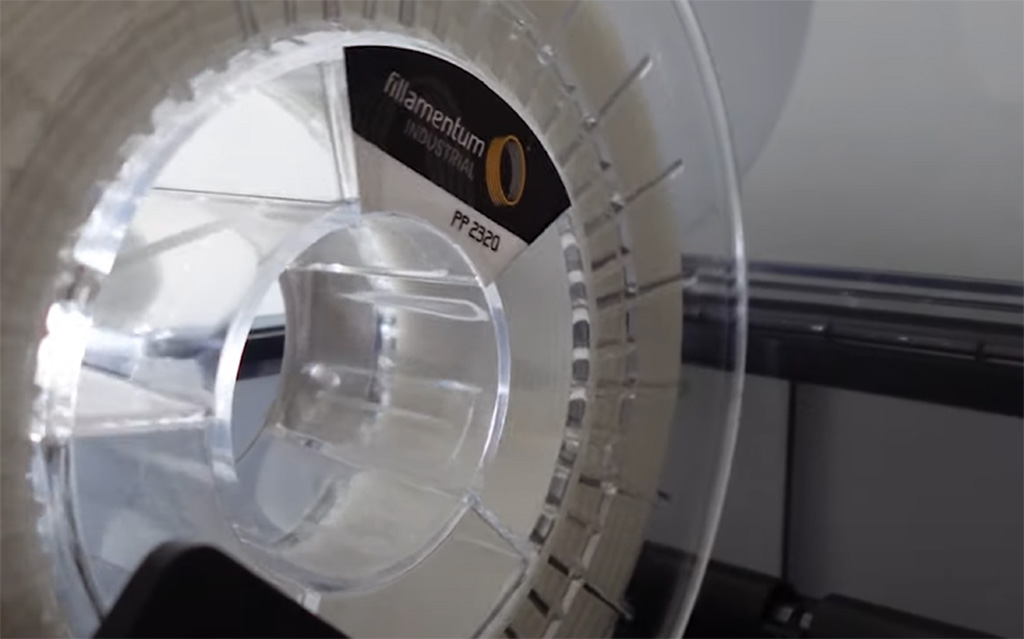

In the innovative sphere of 3D printing, every material challenges us in unique ways. Our latest endeavor explores the capabilities of Polypropylene (PP 2320) by Fillamentum. Noted for being food-safe, we decided to push its limits and showcase its potential in a practical application.

The Endeavor: Functional Finesse with Fillamentum PP

We embarked on a project to print surgical medical tweezers/extended pliers, selecting a design that would truly test PP's mettle. A huge shoutout to Sir_Rob for his Extended Pliers/Tweezers Set V2 design from Cults3D and for allowing us to feature it in our videos. The design's elongated form, typically challenging due to its minimal contact with the build plate, was perfect to demonstrate PP's prowess.

Tackling the Technicalities: Temperature and Airflow

Mastering PP printing hinged on nailing the bed temperature: 85°C for the first layer for impeccable adhesion, then slightly cooler at 77°C for the rest to maintain structural integrity.

The fan speed remained at a consistent 100%, a necessity for PP, which relies on rapid cooling to solidify correctly without distorting. This constant fan activity helped us combat any potential warping, a common foe in prints with extended shapes.

Broad Horizons: Printing an Instrument Tray

Contrasting Sir_Rob's tweezers, we also printed an instrument tray, maximizing the 256x256 mm build plate size. A large print like this usually falls victim to shrinkage, but our precise temperature control and fan speed management proved to be the winning formula against such challenges.

Celebrating the Success

The outcome was nothing short of a triumph for technique and material prowess. The PP prints adhered flawlessly to the build plate without a hint of warping or delamination, showcasing the effectiveness of Filasophia Adhesive and the reliability of our print settings.

Concluding Thoughts: Embracing the Versatility of PP

Our foray into printing with PP wasn't just about pushing the material to its limits; it was a study in how adjusting key print parameters can lead to outstanding results, regardless of the object's size or complexity. By sharing our approach and settings, we hope to inspire and empower your own 3D printing ventures.

While Fillamentum's PP may not be medical-grade, other brands may offer medical-grade options. Our success with Fillamentum PP opens the door to further possibilities and encourages us to keep experimenting.

Thank you for joining us on this journey. Your insights and experiences are what make this community thrive. Let's keep pushing the boundaries of what we can achieve with each layer we print.

Visit cults3d.com to download Sir_Rob’s design