Fanning the Flames of Innovation: 3D Printing with BASF PC/ABS FR

Today's tale from the workshop is all about combining resilience with precision, as we take on the task of printing a complex component with a material that's built to last.

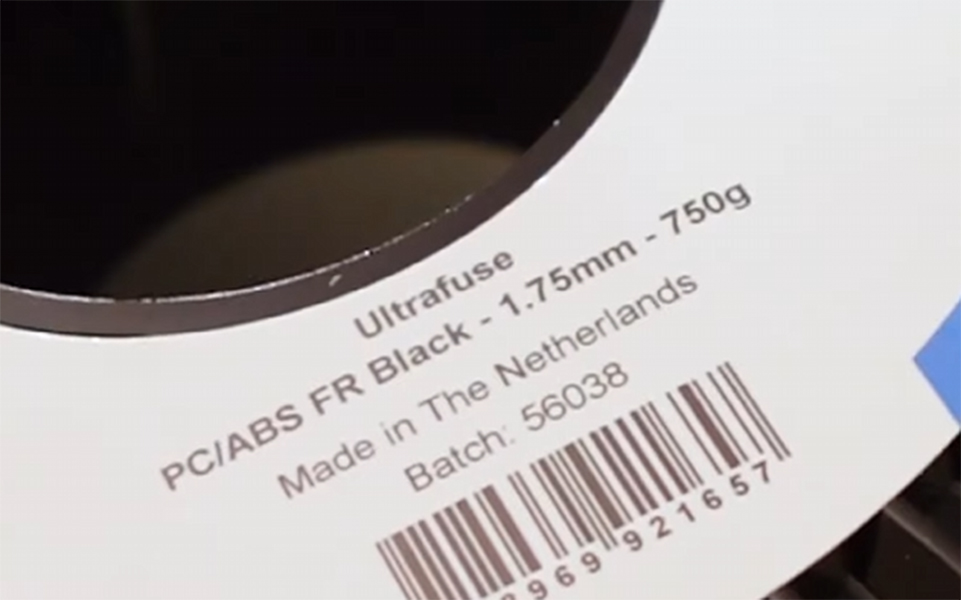

Choosing the Right Filament: BASF Flame Retardant PC-ABS Blend

For our latest project, we reached for the BASF flame retardant PC-ABS blend. This material brings together the high heat resistance of polycarbonate and the flexibility of ABS, making it a go-to for functional parts that need to withstand tough conditions. Perfect for a component like the Toyota FJ40 Blower fan, the design courtesy of ScratchHax on printables.com requires a filament that can handle both detail and durability.

The Printing Process: Smooth and Steady

We jumped straight in with the BASF high-speed profile, trusting the specs to guide us right. True to its reputation, the PC-ABS blend laid down smoothly, layer by layer, with no need for additional adhesion tricks like a brim. It's a testament to the filament's quality and our printer's capabilities that the fan materialized from the build plate fully formed and flaw-free.

The Result: A Standout Print

Taking the freshly printed blower fan in hand, it was clear that our choice paid off. The edges were sharp, the curves uninterrupted, and not a sign of warping in sight. It's moments like this that remind us why we love what we do – seeing a complex design come to life without a hitch is what 3D printing is all about.

Celebrating Adhesion Success

This successful print isn't just about a job well done; it's proof of the adhesive prowess of our printing platform. When the material lays down just right and stays put through the entire process, it's a victory for the machine, the material, and the maker.

Visit printables.com to download Ford FJ40 Blower designed by ScratchHax